CAD/CAM manufacture

Oracle Precision understand the need for not only a ‘right first time’ mentality but also the requirement to keep costs and lead times to a minimum.

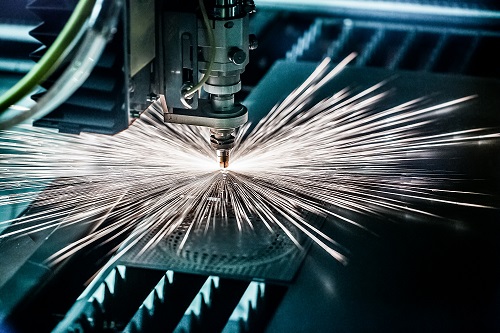

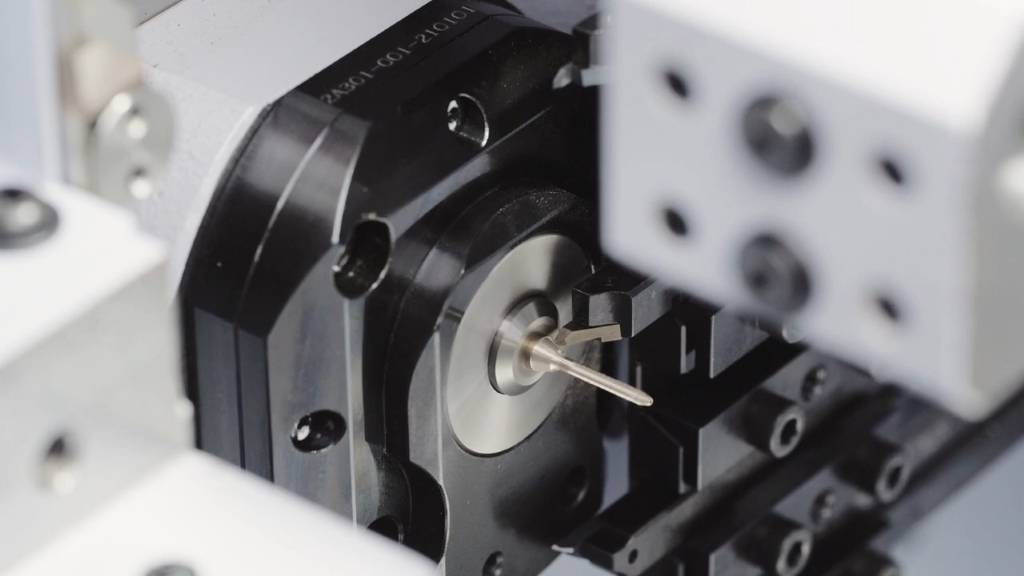

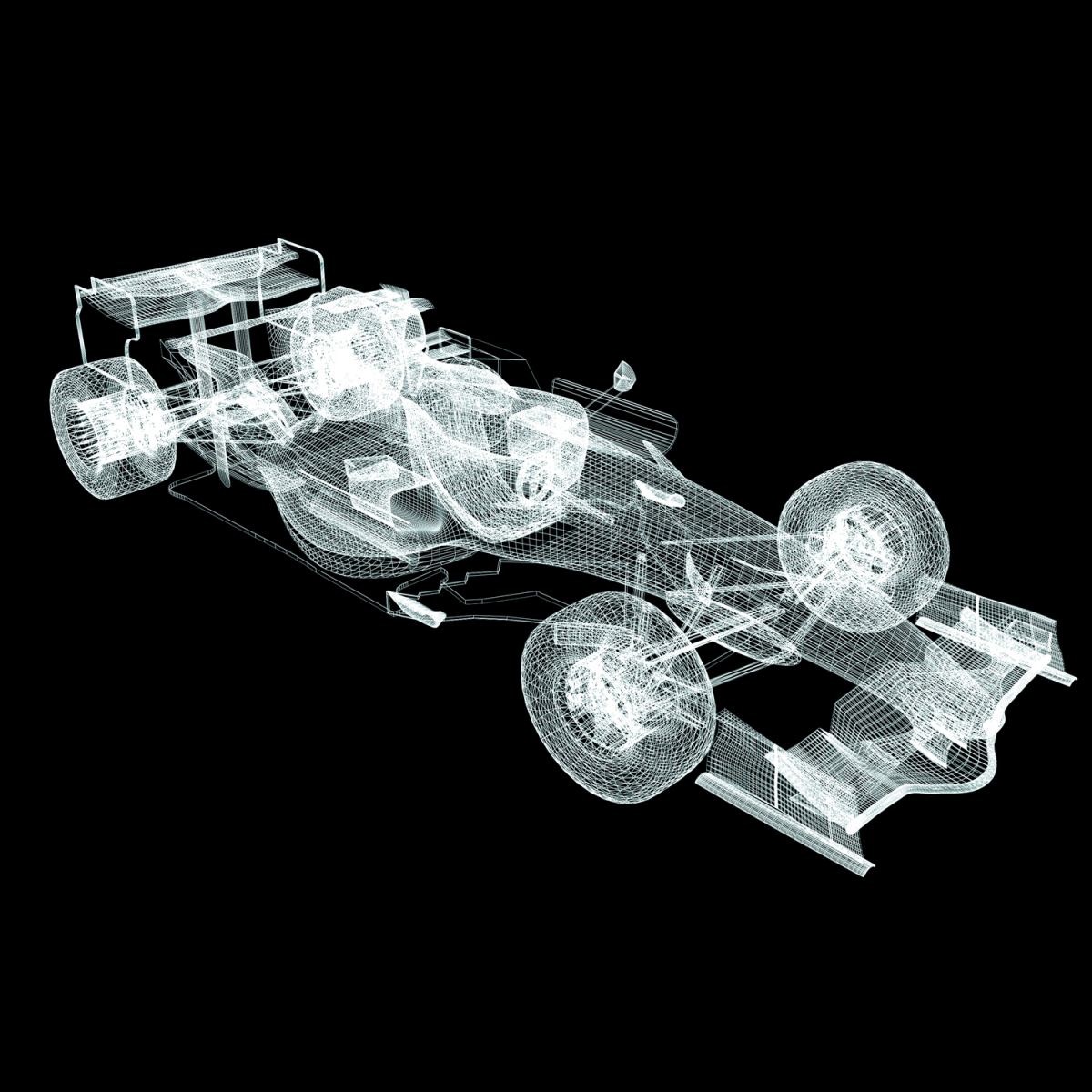

This is why we employ state of the art manufacturing and inspection techniques, including the use of the latest Computer Aided Design/Manufacture (CAD/CAM) technology. This methodology allows us to provide an exacting and compliant service to our customers with the advantages of reduced costs and lead times. The process involves the acquisition of a customer 3D model, model verification to ensure finished part compliance, part programme construction utilising the latest methodologies in cutting technology and pre-determined machining parameters, direct part programme download to the individual CNC machine tool via DNC, programme prove-out, component manufacture and inspection.

Through 3D model and programme verification at all critical stages of the process, including pre-determined key stage and final inspection protocols, our customer can be assured of compliance at all times.