Laser marking

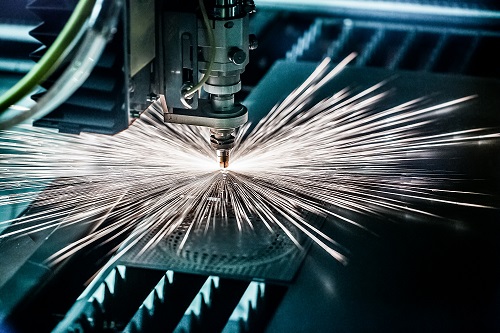

Laser marking (of which laser engraving is a subset) has steadily become the preferred and in some cases required process for a range of industrial sectors requiring direct part marking.

From aerospace and medical to marine and ministry of defence applications. This is because permanently and accurately marking machined parts with clear identification is crucial for the regulation and tracking of components throughout product life cycles.

Oracle Precision has invested in fibre laser marking technology from Needham Coding, whose range of fibre laser systems are renowned for their superior accuracy and reliability. Our CNC laser engraving machines can, amongst other applications, achieve the following:

- Improve quality control procedures by adding traceable information to components.

- Include logos and other branding information clearly and permanently.

- Add bar codes, date codes, serial numbers, and other details with pinpoint accuracy.

- Add CE marking for EU compliance, as well as other permanent compliance indicators.

- Mark cables, printed circuit boards, and other electronic components.

Laser Engraving

One of the most common processes, laser engraving involves removing material from the workpiece’s surface, leaving a depression as a result. A laser engraving machine can work with a variety of materials, including metals, plastics, wood, carbon fibre, glass, and more.

Our Laser Engraving and Marking Machines

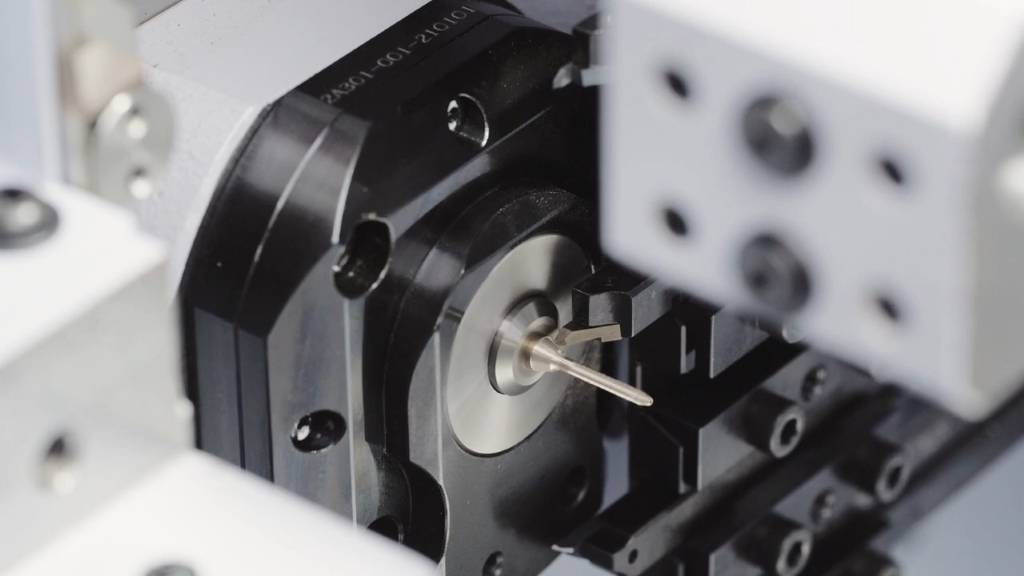

Oracle Precision has several specialist laser engraver machines for industrial applications. Our high-performance laser beam marking system from Needham Coding uses a data matrix process to mark all types of metals and engineering plastics, creating minutely precise text and image engravings from DXF files. It has a maximum focal window of 100mm x 100mm and utilises the latest fibre optic technology for speed and consistency. The machine’s 4-axis rotary system means it can mark many areas of the same product while rotating it, often completing work within a single set-up for maximum efficiency.

We have also invested in a HK marking system from Hahn & Kolb, who have been researching and developing laser engraver and marking machines for over 30 years. This machine uses diode pumped laser technology to produce an extremely fine focal diameter, providing a high level of intensity as a result. This laser is particularly suited to metal annealing.

To find out more about our laser engraving systems and the work we can do for you, get in touch with Oracle Precision by phoning 01226 350 010 or emailing us at

info@oracle-precision.co.uk.

What is Laser Marking?

This process involves a beam of light interacting with a material surface, altering its appearance with permanent and precise marks. The results are non-damaging, making marking particularly suited to materials that cannot have labels. The low stress impact of this method also makes it ideal for industries where quality and strength are critical, such as aerospace engineering and automotive manufacturing.

Laser beam marking processes are suitable for a wide range of materials, including metals (for instance aluminium, stainless steel, brass, copper, chromium, and titanium), ceramics, and plastics (such as ABS, Plexiglas, PBT, polycarbonate, and polyethylene; plastic materials can become darker in colour with the blackening process or lighter with foamed marking). These processes most commonly include laser annealing (changing material colour through localised heating; suitable for ferrous metals and titanium only), ablation (partial removal of coating layers from the material), and laser engraving.

Subcontract Laser Marking Services

We provide a range of sub contract machining services across our numerous CNC capabilities, from 5 axis machining to prototype machining. As an ISO 9001, AS 9100 and ISO 13485 accredited precision engineering company, we are perfectly placed to complete sub contract work for a variety of industries.

Applications

There are many industries that can benefit from laser marker systems, though not all have specialised marking machines in-house. This is where we come in! Oracle Precision works with a diverse range of clients with different component marking requirements and compliance procedures to follow. Some of the sectors we have worked with include:

Aerospace Laser Engraving

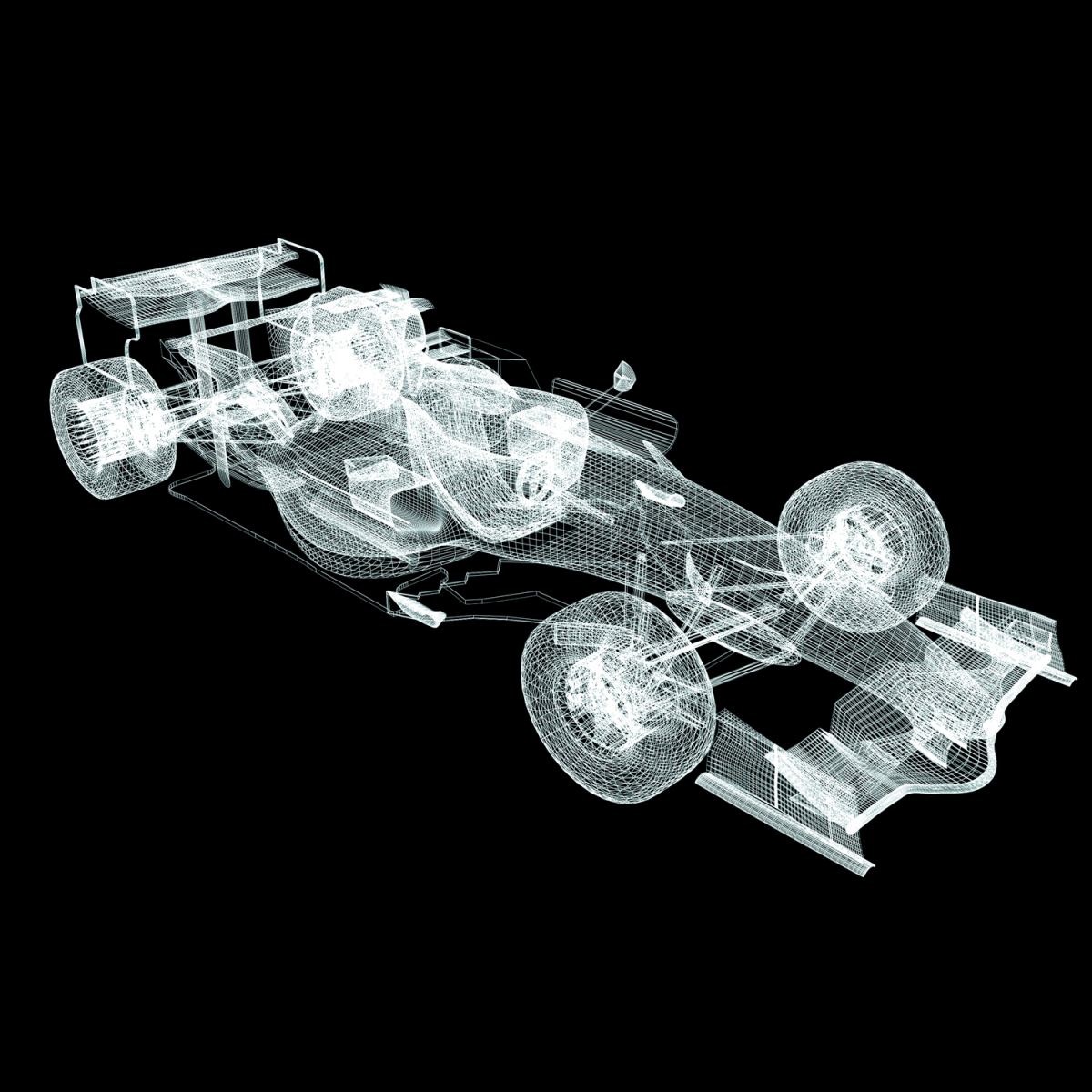

Direct Part Marking (DPM) is a requirement for aerospace industry parts, as this helps with tracking a part’s entire life cycle for safety and regulation reasons. The permanent nature of laser beam marking makes this ideal for a variety of aerospace direct part marking procedures. Oracle’s experienced aerospace CNC engineers can advise you on how best to achieve DPM using lasers.

Medical Device Marking

Titanium and steel medical devices greatly benefit from a Unique Device Identification (UDI), which is used to identify individual devices for distribution and lifecycle purposes. The FDA introduced this as a requirement for medical devices in the United States in 2013; new Medical Device Regulations mean the EU will soon follow suit. Marking is ideal for adding this crucial information to a range of medical devices and we are proud to offer this as part of our work for the medical sector.

Laser Marking

Find out more about our bespoke laser engraving and marking services by getting in touch.