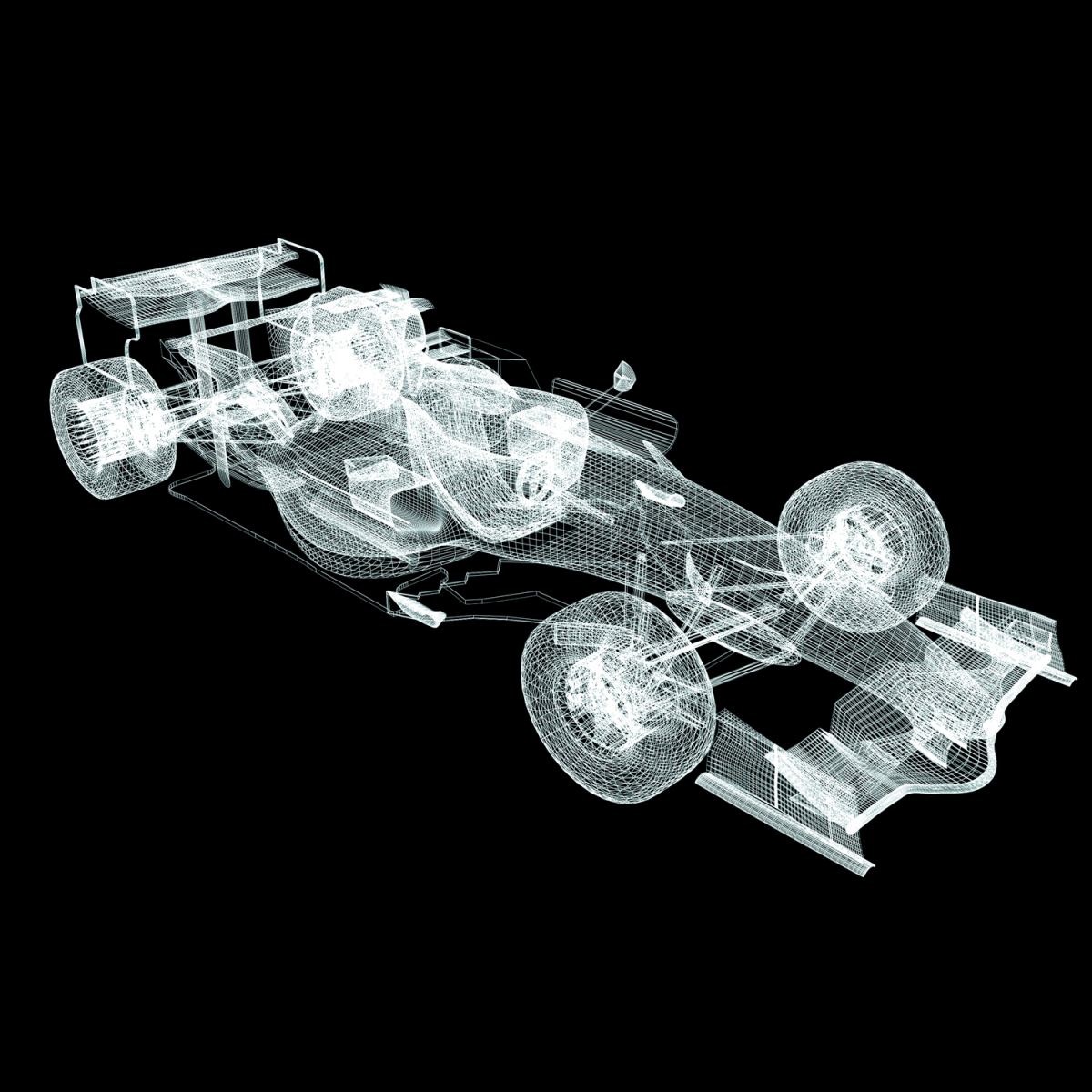

3D machining

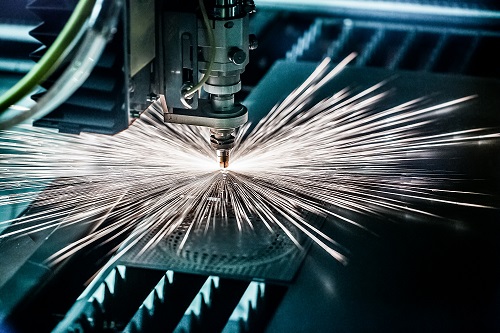

Oracle Precision is proud to be able to provide a range of unparalleled precision machining services to a variety of diverse industry sectors by utilising state of the art technology and the latest advances in manufacturing techniques.

One particular area of expertise is that of 3D machining where component complexity, whilst inherently providing a challenge, is able to be approached in such a manner as to simplify the manufacturing process in order to supply components not only to exacting customer specifications, but with significantly reduced lead times, thus resulting in lower costs.

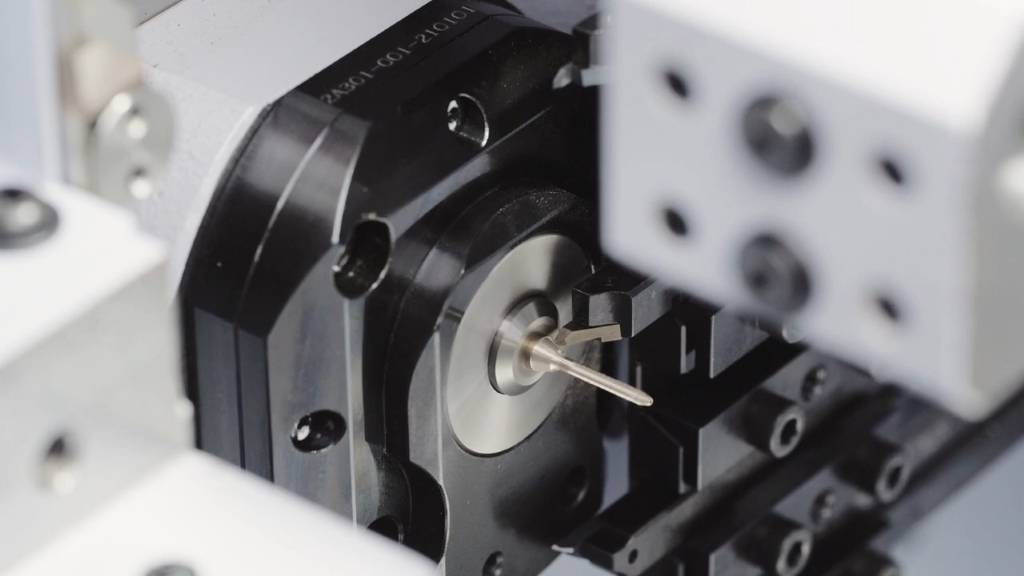

The total manufacturing process typically involves the procurement of a client(s) 3D CAD model, model verification, part programme construction direct from the 3D model, programme verification, direct program transfer via DNC, through to component manufacture and inspection with a minimum amount of set-up / re-fixturing / re-tooling etc.

Additionally, we also have the capability to run multiple components (nesting), in a variety of exotic and less exotic materials, in one set-up thus keeping costs and lead times to a minimum.